In-Space Manufacturing

Revolutionizing the Final Frontier

A gift for all of you readers — Beautiful Space & Rocket-themed phone wallpapers

Our next project on “Aircraft and the Science of Flight” is coming soon.

Now back to today’s article—

"The future of space exploration lies not just in reaching the stars, but in building our future among them."

In-space manufacturing (ISM) is one of the most exciting advancements in space exploration and technology, marking a significant shift in how humanity can sustain long-term missions beyond Earth. Traditionally, everything needed for space missions—equipment, tools, structures, and even food—had to be launched from Earth. However, the concept of ISM changes this paradigm, allowing for the production and assembly of materials directly in space. This capability not only reduces the cost and complexity of space missions but also opens new avenues for deep-space exploration and the development of space-based industries.

What is In-Space Manufacturing?

In-space manufacturing refers to the process of producing goods and materials in space rather than on Earth. This concept leverages the unique environment of space, including micro-gravity and the vacuum of space, to manufacture items that would be difficult or impossible to create on Earth. ISM encompasses a wide range of activities, from the 3D printing of tools and spare parts on the International Space Station (ISS) to the potential fabrication of large structures, such as satellites or even space habitats, in orbit or on other celestial bodies like the Moon or Mars.

How is In-Space Manufacturing Done?

ISM is carried out using various advanced technologies that are adapted to function in the harsh and unique conditions of space. Here are some of the primary techniques and technologies explored in ISM:

3D Printing (Additive Manufacturing)

One of the most prominent techniques in ISM is 3D printing. This process involves layering materials, such as plastics, metals, or even regolith (lunar or Martian soil), to create objects. NASA and private companies like ‘Made In Space’ (now Redwire Space, Inc.)have successfully used 3D printing aboard the ISS to create tools and spare parts, reducing the need to launch these items from Earth. The flexibility of 3D printing allows astronauts to produce objects on-demand, a critical capability for long-duration missions where resupply opportunities are limited.

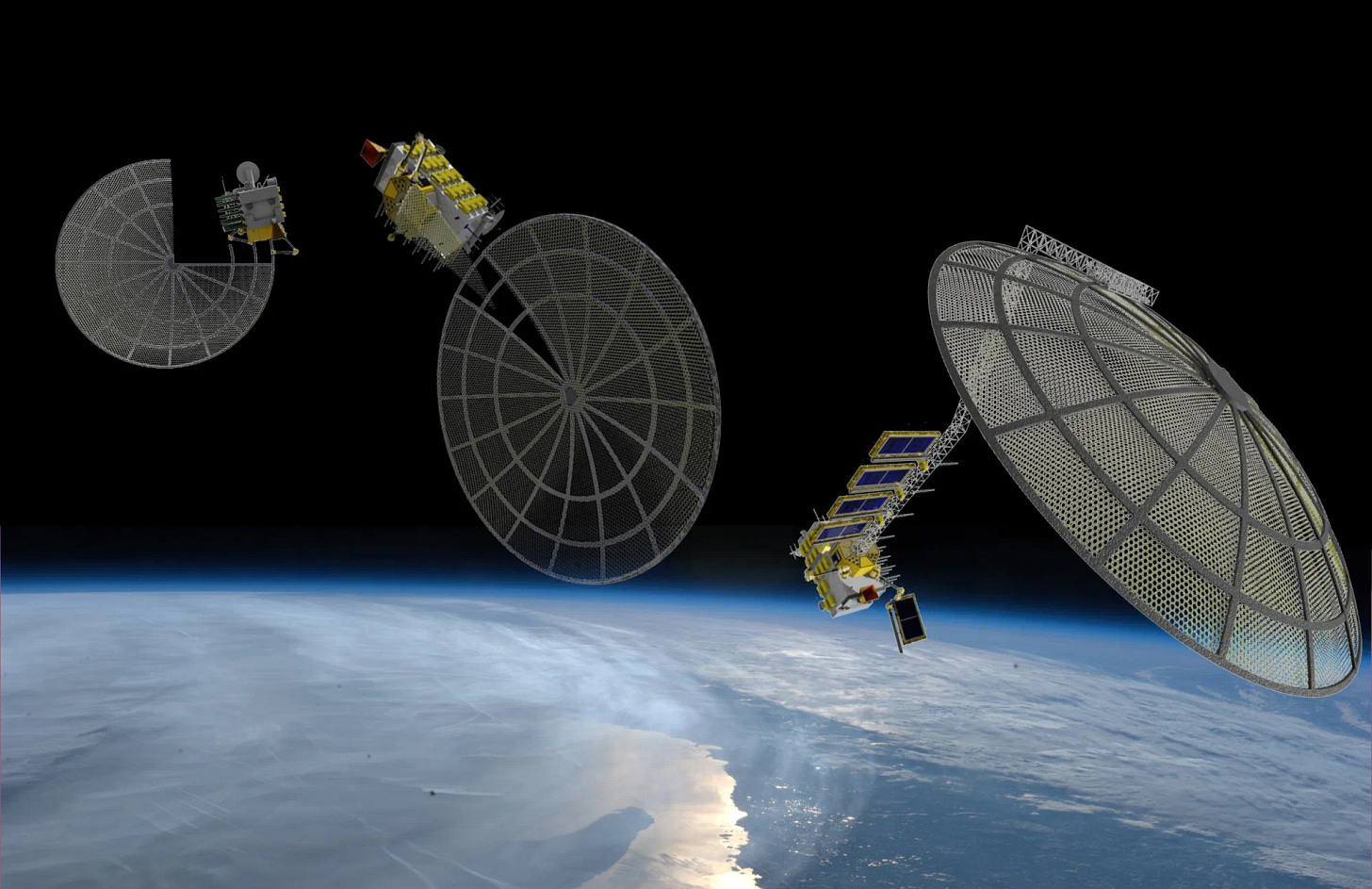

Automated Assembly and Construction

As space missions extend beyond Earth's orbit, the need for large structures—such as solar arrays, antennas, or space habitats—becomes more critical. In-space automated assembly and construction techniques are being developed to build these structures directly in space. These techniques include robotic arms and autonomous drones capable of piecing together modular components into larger configurations. For example, NASA's Archinaut project aims to develop robotic systems that can assemble spacecraft components in orbit, reducing the need for massive rockets to launch fully assembled structures.

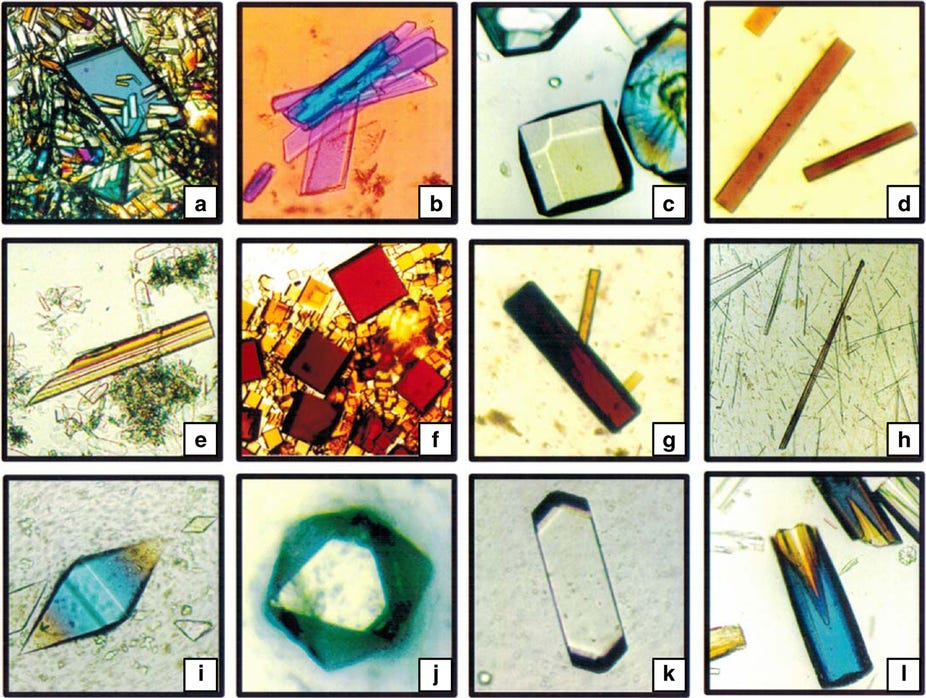

Material Processing and Refinement

In addition to building structures, ISM also involves processing raw materials found in space. This could include refining metals from asteroids, extracting water from lunar ice, or converting Martian regolith into construction materials. Techniques like sintering, where materials are heated below their melting point to bond them together, and electrolysis, which can extract oxygen from lunar regolith, are being explored to utilize in-situ resources for manufacturing in space.

Biomanufacturing

Another frontier in ISM is biomanufacturing, which involves producing biological products, such as food, medicine, or even human tissues, in space. Microgravity can influence biological processes in unique ways, potentially leading to advancements in medicine or food production for astronauts. Research is ongoing to explore how microorganisms can be harnessed to produce essential supplies during space missions, reducing the reliance on Earth-based resources.

Pros of In-Space Manufacturing

ISM offers numerous benefits that could significantly enhance space exploration and commercialization:

1. Cost Reduction

Launching materials from Earth is expensive, with the cost of sending payloads to space often exceeding thousands of dollars per kilogram. ISM can drastically reduce these costs by manufacturing what is needed directly in space, minimizing the payload that needs to be launched from Earth.

2. Mission Flexibility

ISM provides greater flexibility in space missions. Instead of carrying every possible tool or spare part, missions can carry raw materials or manufacturing equipment to produce items as needed. This capability is especially valuable for long-duration missions where resupply is challenging.

3. Sustainability

By utilizing resources found in space, such as lunar regolith or asteroid metals, ISM can create a more sustainable approach to space exploration. This reduces the dependency on Earth-based resources and supports the development of self-sustaining colonies on other planets or moons.

Challenges in In-Space Manufacturing

While ISM holds great promise, there are also significant challenges and drawbacks that need to be addressed:

1. Technical Challenges

The harsh environment of space presents numerous technical challenges for ISM. Equipment must operate in microgravity, extreme temperatures, and high levels of radiation. Ensuring the reliability and durability of manufacturing systems in these conditions is a significant hurdle.

2. High Initial Investment

Developing and deploying ISM technologies requires substantial upfront investment. The research and development costs, combined with the expense of launching and maintaining manufacturing systems in space, can be prohibitive, especially for private companies without government support.

3. Regulatory and Ethical Considerations

As ISM becomes more feasible, questions about the regulation of space resources and the ethical implications of space-based manufacturing will need to be addressed. International treaties and agreements, such as the Outer Space Treaty, may need to be updated to account for the commercialization and exploitation of space resources.

Future Scope of In-Space Manufacturing

The future of ISM is incredibly promising, with numerous potential applications that could revolutionize space exploration and the development of space industries:

Deep-Space Exploration

Space-Based Industries

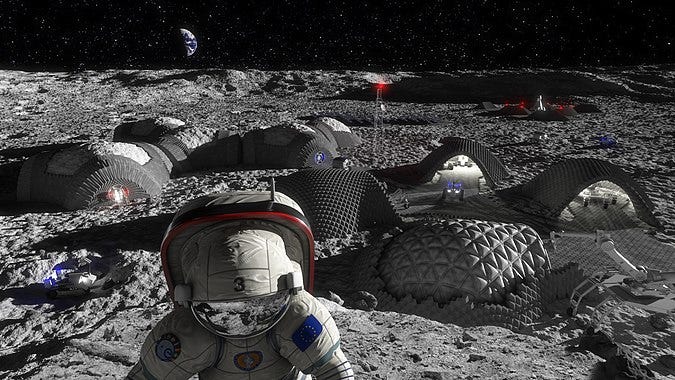

Space Habitats and Colonization

Interplanetary Supply Chains

In-space manufacturing represents a transformative shift in how humanity approaches space exploration and the development of space-based industries. By leveraging the unique environment of space and utilizing advanced technologies like 3D printing, automated assembly, and material processing, ISM has the potential to reduce costs, enhance mission flexibility, and support the long-term sustainability of space missions.

While there are significant challenges to overcome, including technical, financial, and regulatory hurdles, the potential benefits of ISM are vast. The future of ISM is bright, with the promise of enabling deep-space exploration, establishing space-based industries, and even supporting the colonization of other planets. As humanity continues to push the boundaries of exploration, in-space manufacturing will be a critical tool in our quest to explore, inhabit, and thrive in the final frontier.