Starship: Engineering the Return Journey

Navigating the Challenges and Innovations of Landing Rockets

The Space Deck got 200% funding on Kickstarter. 4 days left if you wish to pre-order.

Recently we witnessed the third test flight for Starship rocket, which travelled halfway around the Earth before it re-entered the atmosphere. Elon Musk’s SpaceX has successfully carried out the longest test flight of its massive Starship rocket, but it disintegrated on its return to Earth. The module was destroyed while approaching its landing point in the Indian Ocean.

The pursuit of reusable rockets has been a significant shift in space exploration methodologies, primarily led by companies like SpaceX with their Falcon rockets and the Starship. The traditional model of space exploration involved single-use rockets, where parts would often be discarded into the ocean or left to burn up in the atmosphere after launch. Despite the apparent benefits, the process of landing a rocket back on Earth or at sea presents numerous technical challenges and complexities.

Today we will cover the various aspects as to why it's so difficult to achieve this feat and looks at some solutions engineers are exploring.

The Technical Challenges

Re-entry heating and aerodynamic forces: Upon atmospheric re-entry, rockets experience extreme heating and aerodynamic forces due to air resistance and friction. They must withstand incredibly high temperatures as friction with the Earth's atmosphere generates heat, risking damage or destruction to the vehicle. This necessitates the use of heat shields and other thermal protection systems to prevent damage or destruction. Additionally, maintaining aerodynamic stability is essential for a controlled descent and successful landing.

Fuel management and weight optimization: Rockets need to reserve enough propellant for the return trip and landing, which means they can't use all their fuel to reach orbit or their destination. This requirement reduces the payload capacity, affecting the efficiency and cost-effectiveness of the mission. The heavier the rocket, the more fuel it needs to slow down for a safe landing. This creates a weight vs. fuel conundrum. Balancing payload and fuel for the return is a complex optimization problem, especially when considering the rocket's mass changes as it consumes fuel during flight.

Guidance, navigation, and control systems: Accurately controlling the rocket's orientation and trajectory requires sophisticated guidance, navigation, and control (GNC) systems. These systems need to account for various factors, such as atmospheric disturbances, wind shear, and GPS inaccuracies, to ensure precise landings. Landing a multi-ton rocket on a designated pad or drone ship in the middle of the ocean requires pinpoint accuracy. Sophisticated guidance systems with real-time feedback from sensors are crucial to maneuver the rocket during descent and achieve a controlled touchdown. Even minor deviations can lead to a catastrophic crash.

Landing stability and leg design: Designing robust and lightweight landing legs that can absorb the impact forces while maintaining stability is a significant challenge. These legs must be able to support the rocket's weight and prevent tipping or structural damage during touchdown.

Propulsive landing: Propulsive landing involves using rocket engines to slow down the rocket's descent and perform a soft touchdown. This requires accurate throttling, precise timing, and effective control algorithms to ensure the correct amount of thrust is applied.

Potential Solutions

Engineers are constantly innovating to overcome these hurdles. Here are some solutions being explored::

Thermal protection systems: Advanced materials and thermal protection systems are being developed to withstand the extreme heat of re-entry. These systems include ablative heat shields, which slowly burn away during re-entry, and reusable ceramic tiles that can resist high temperatures. New materials and designs aim to make these shields more effective and lighter, contributing less to the overall mass of the vehicle.

Fuel management optimization: Engineers use complex algorithms to optimize fuel consumption, burn rates, and trajectory calculations to ensure enough fuel is available for landing. This often involves multiple engine burns during descent to reduce velocity gradually. Additionally, techniques like aerial propellant transfer could potentially allow rockets to refuel in orbit, although this technology is still in the conceptual or testing phase.

Advanced GNC systems: New guidance, navigation, and control systems are being developed to improve landing accuracy and stability. These systems incorporate machine learning algorithms, improved sensor fusion techniques, and adaptive control strategies to handle various environmental conditions.

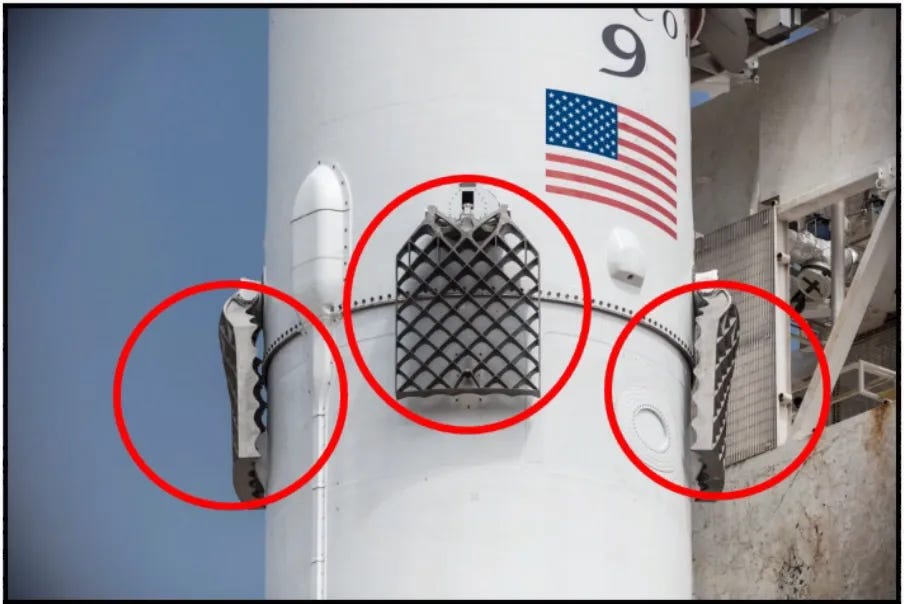

Robust landing leg designs: Engineers are exploring various materials, geometries, and shock absorption mechanisms to create more robust and lightweight landing legs. This includes the use of composites, carbon fiber, and advanced aluminum alloys for improved strength-to-weight ratios. One can notice how the Falcon9 landing legs have evolved over time.

Enhanced propulsive landing control: Engineers are refining propulsive landing control algorithms and deep throttling capabilities to achieve smoother and more precise landings. This includes better engine gimbaling and thrust vectoring systems to provide greater control authority. Hypersonic grid fins, are movable control surfaces steer the rocket during descent, similar to a plane's ailerons. SpaceX's Falcon 9 and Starship utilize grid fins for directional control during re-entry.

In conclusion, landing rockets back on Earth or at sea presents numerous challenges in areas such as aerodynamics, thermal protection, fuel management, and control systems. However, ongoing research and development efforts are producing innovative solutions to address these complexities, paving the way for reusable rocket technology and more sustainable space exploration.

The Space Deck got 200% funding on Kickstarter. 4 days left if you wish to pre-order.